Technical and Testing

Transparent High Tenacity Cover

Material – Double wall woven polyester

Weave – Breathable and snag resistant construction

Air Openings – Measurable hole openings of approximately 0.004 sq. inch.

Finish – Polytetrafluoroethylene (PTFE) similar to Teflon®

Chemical Reaction – The sling manufacturer should be

consulted before using in chemically active environments.

Coefficient of friction – Low

Abrasion – Surface resistance comparable to opaque covers.

Hex bar abrasion test per Federal Std-191

Method 5309 Cycles-2500

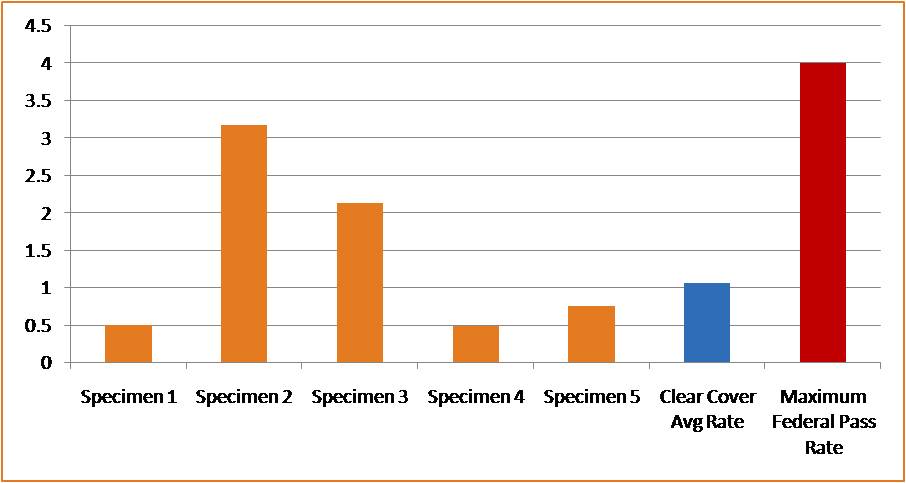

Flammability – Average burn rate = 1.06 inches per minute (maximum allowable Federal rate is 4.0 inches per minute). Test included five specimens of 3 inch wide Clear Cover™ 12.5 inches in length per Horizontal burn test Fed-Std-191A Method 5906 – Passed

Horizontal Burn Test Fed-Std-191A Method 5906, Inches per Minute

Observations: Four of the five specimens self extinguished. There was no dripping of the fiber onto the base plate of the test chamber. Smoke generated by the burning was minimal.

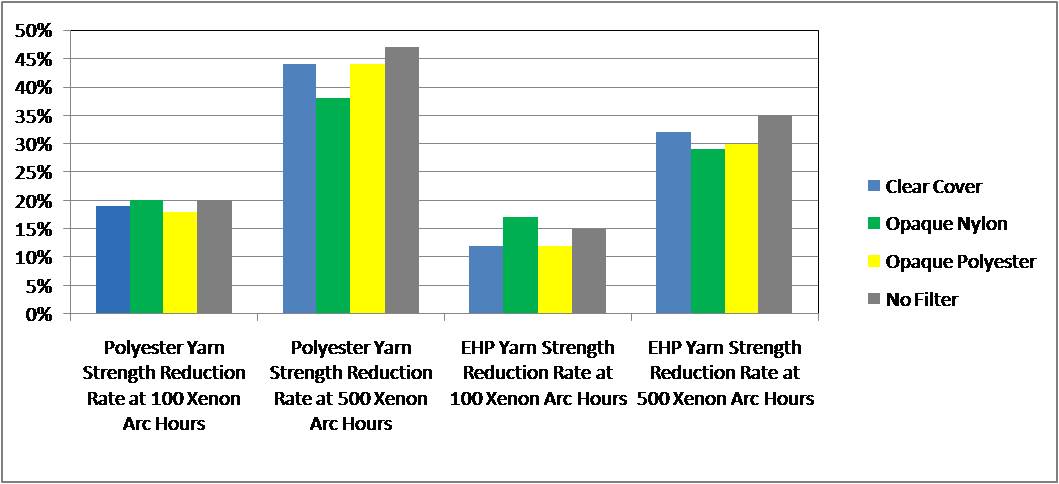

UV (ultraviolet light) resistance – Transparent monofilaments are an ultraviolet light resistant polymer. UV resistance is equal to that of polyester and nylon opaque multifilament covers.

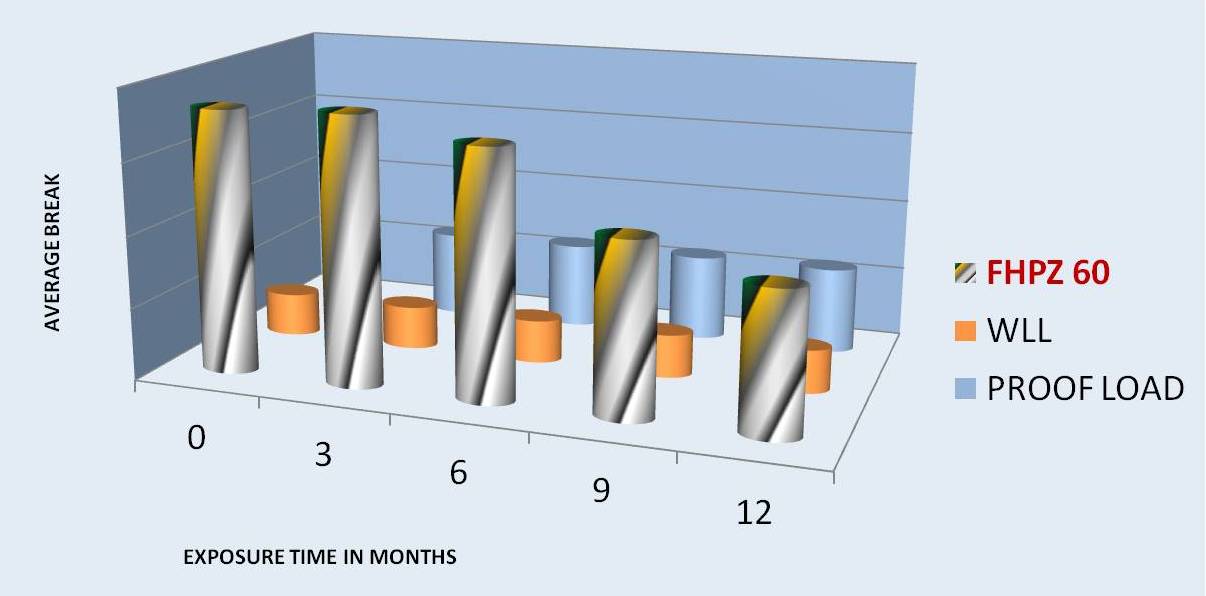

UV Protection – Comparison of Clear Cover® to Opaque

Note: Baseline breaking strengths of unexposed yarns average a range of 5.74% to 8.24%. Breaks are within a range of 2% to 6%, below and within the average. Xenon arc lamp exposure, 214 hrs = 3 months, 428 hrs = 6 months, 624 hrs = 9 months of actual sunlight. Simulated testing could equate to years of direct sunlight since typically the sun shines directly less than half of the time. This test was conducted using single wall covers for comparison only.

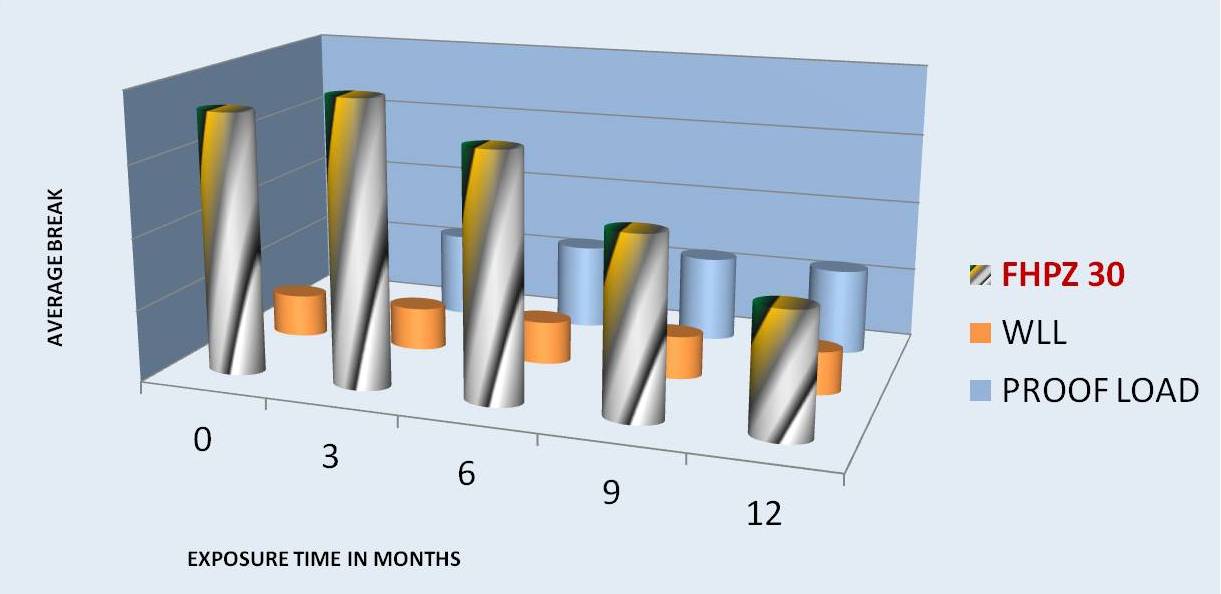

FIRST® REAL-TIME ONE YEAR CONTINUOUS CLIMATIC EXPOSURE TEST OF HIGH PERFORMANCE ROUNDSLINGS

Twenty-five FHPZ 30'S and twenty-five FHPZ 60's were manufactured using control lots of both Clear Cover® and EHP® core yarns, with consistent manufacturing methods and machinery.

Five slings of each group were broken to establish an average break at zero exposure time. The remaining 40 slings were then secured on pallets that were placed on the rooftop unprotected. Five each of the FHPZ 30's and FHPZ60's were removed and broken at intervals of 3 months, 6 months, 9 months and 12 months of continuous climatic exposure.

EXPOSURE CONDITIONS AT TEST SITE

Temperature - -2°F (-17°C) to 100°F (38°C)

Precipitation - 32 in (813 mm)

UV Index Low to Extreme - 2 to 11.5

Gust Wind - 131 mph (211 kph)

Photos were taken  at each quarter. No visible signs of mildew at any test interval. At one year a negligible amount of surface debris was observed.

at each quarter. No visible signs of mildew at any test interval. At one year a negligible amount of surface debris was observed.

After a year of severe and continuous climatic exposure, FHPZ 30 and FHPZ 60 FIRST® Inspectable Roundslings both achieved breaks ABOVE THE PROOF LOAD (TWICE THE WORKING LOAD LIMIT).

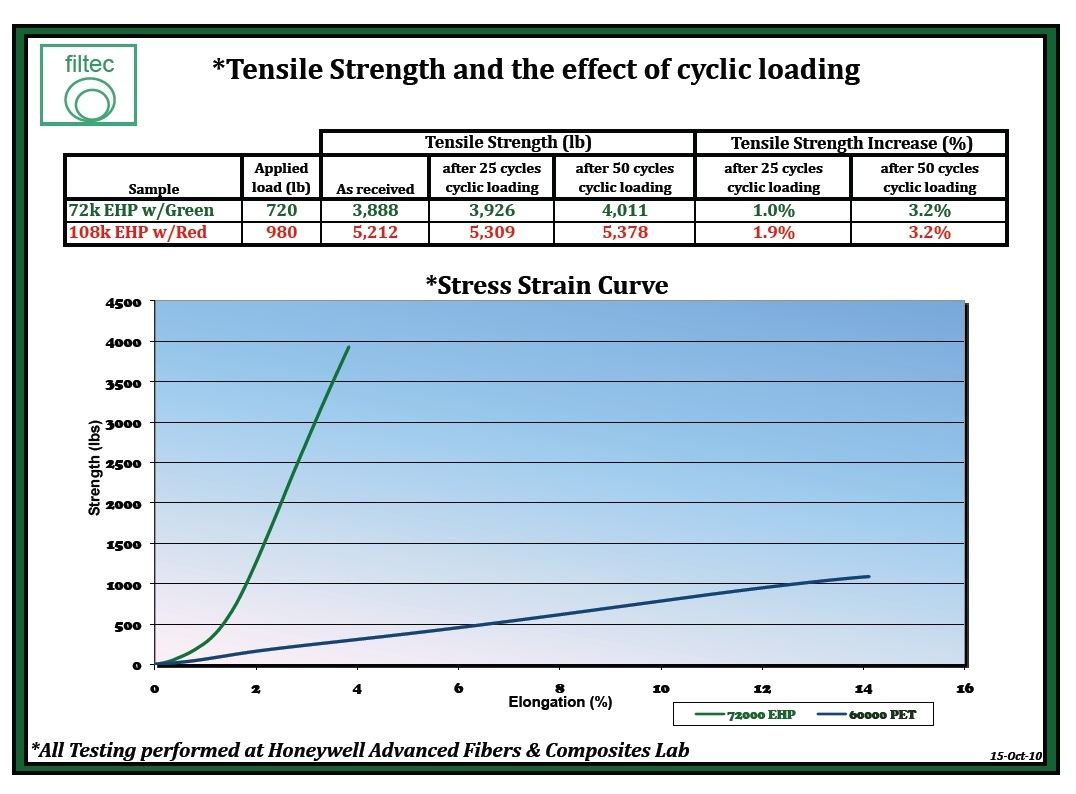

FIRST® Sling's FHPZ High Performance Core Yarns

Filtec Precise, Inc. of Tabor City, NC, and Baesweiler and Kamenz, Germany manufactures both the polyester and EHP®, high performance core yarns used by the FIRST® manufacturing team to produce FP, Polyester Roundslings and FHPZ High Performance Roundslings. EHP® is MADE IN THE USA.

EHP® Engineered Hybrid Power® high performance yarns feature Honeywell Spectra® fiber.

HONEYWELL SPECTRA® FIBER

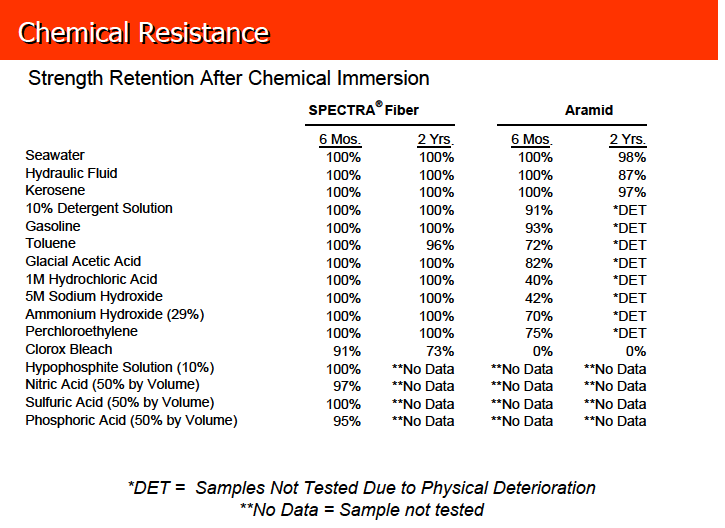

FIRST® FHPZ CORE YARN CHEMICAL RESISTANCE TESTING

Material - Custom blend of HMPE (high-modulus polyethylene) Spectra® and Aramid (a class of heat-resistant and strong synthetic) fibers.

Breaking Strengths – Certified

Elongation – Less than 4% at break